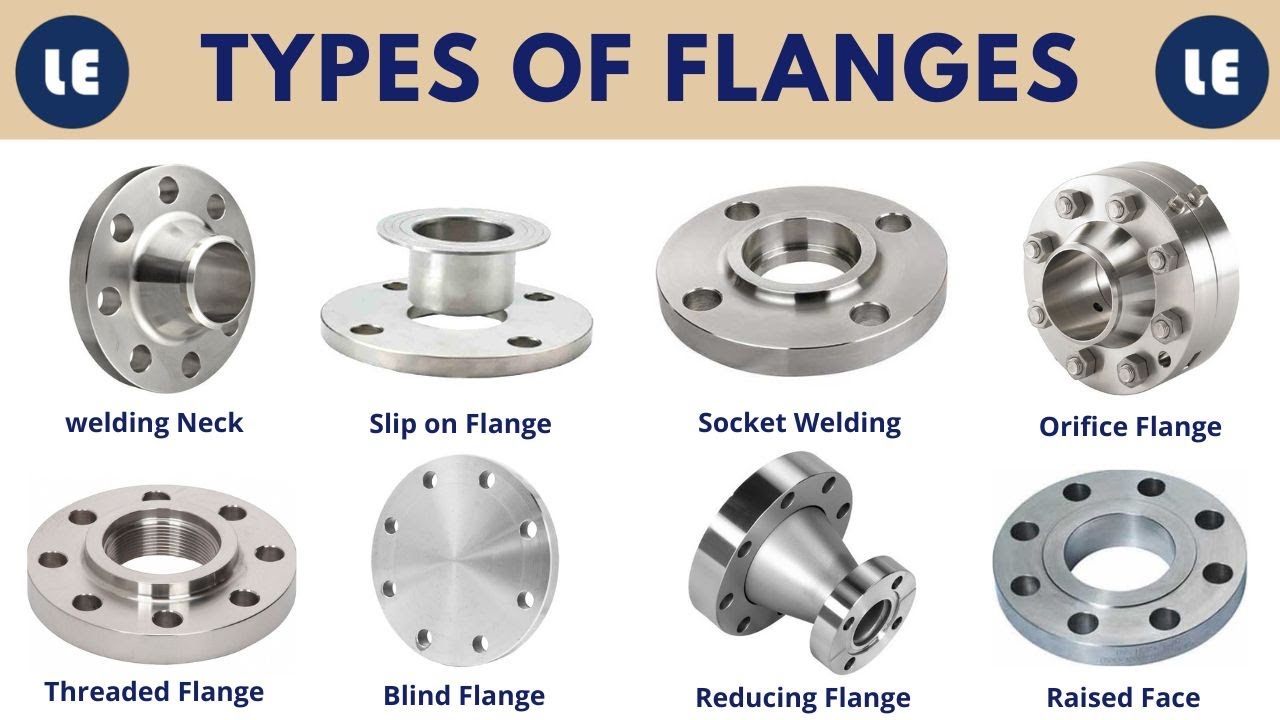

Okay, so, let’s talk about this whole “flange Johnson” thing. I was putting together this piping system, you see, just a regular day in the shop, and I needed to connect a bunch of pipes. Now, I’ve dealt with all sorts of flanges before – slip-ons, weld necks, you name it. But this time, I was really focused on getting a good, solid connection without any fuss.

I started by looking at the different types of flanges I had lying around. There were a bunch of stainless steel ones, some Monel, and a few others that I couldn’t even identify. I knew I needed something tough and reliable. The project was kind of a big deal, you know? Like, industrial-grade stuff. Petrochemical, oil and gas, the whole nine yards.

So, I grabbed a few different flanges and started experimenting. First, I tried a weld neck flange. It seemed pretty strong, but welding it was going to be a pain. Then, I played around with a slip-on flange. Easier to install, for sure, but I wasn’t convinced it would hold up under the pressure I was expecting.

- Tried the weld neck first, seemed strong.

- Welding it was a hassle, though.

- Moved on to the slip-on, much easier.

- But was it tough enough? Not sure.

I spent a good chunk of time just fiddling with these things, trying to figure out the best way to get a perfect seal. I even considered calling up this guy I know who works at Texas Flange. They are experts in large diameter flanges. Thought he might have some insider tips. But I figured I could crack this on my own.

After a lot of trial and error, I finally settled on using a combination of flanges that gave me the best of both worlds. I used a weld neck for the high-pressure areas and slip-ons for the rest. It was a bit of extra work, but I was confident that this setup would be solid as a rock. I just wanted to make sure, you know. Don’t wanna compromise on quality.

The Final Setup

In the end, I managed to get the whole system up and running, and it’s been working like a charm. No leaks, no issues, nothing. I have to say, that I used carbon, stainless and some alloy materials. It was a bit of a learning curve, figuring out which flange to use where, but I’m pretty proud of how it all turned out. And hey, at least I didn’t have to bother that guy from Texas Flange!

There you have it. My little adventure with flange Johnson. Hope this was helpful to someone out there. It’s all about finding the right tool for the job, and sometimes that takes a little bit of elbow grease and a whole lot of patience.